INNERA TECHNOLOGICAL SOLUTIONS

OUR SPECIALISATION

OUR CAPABILITIES

FOR YOUR EFFICIENCY

Our services

Development of New Biogas Projects

We develop Biogas Projects from the beginning till their start up.

Biogas Plant Performance Optimization

We provide Consulting Services to improve the performance of the plant.

Development of Biomethane Projects

We provide Consulting Services for Biogas upgrading and Biomethane production, either for fuel (CNG) or for injection into the Natural Gas Network.

Contact us

Development of New Biogas Projects

- Biogas Plant Viability Studies

- Guidance on the Energy mix of raw materials

- Guidance to achieve the optimal Design & Technology flexibility of the plant, based on the mix of raw materials

- Project Management of the construction

- Commissioning & Start up of the Plant

Biogas Plant Performance Optimization

- Availability of special additives and reinforcement products of research and biotechnology of SCHAUMANN Bioenergy, to strengthen and stabilize the biology of anaerobic digestion.

- Immediate availability of the products from the warehouse in Thessaloniki.

- Free sample analyses at SCHAUMANN research laboratory in Germany.

- Specialized Seminars for various Biogas topics, with the participation of SCHAUMANN Bioenergy Consultants.

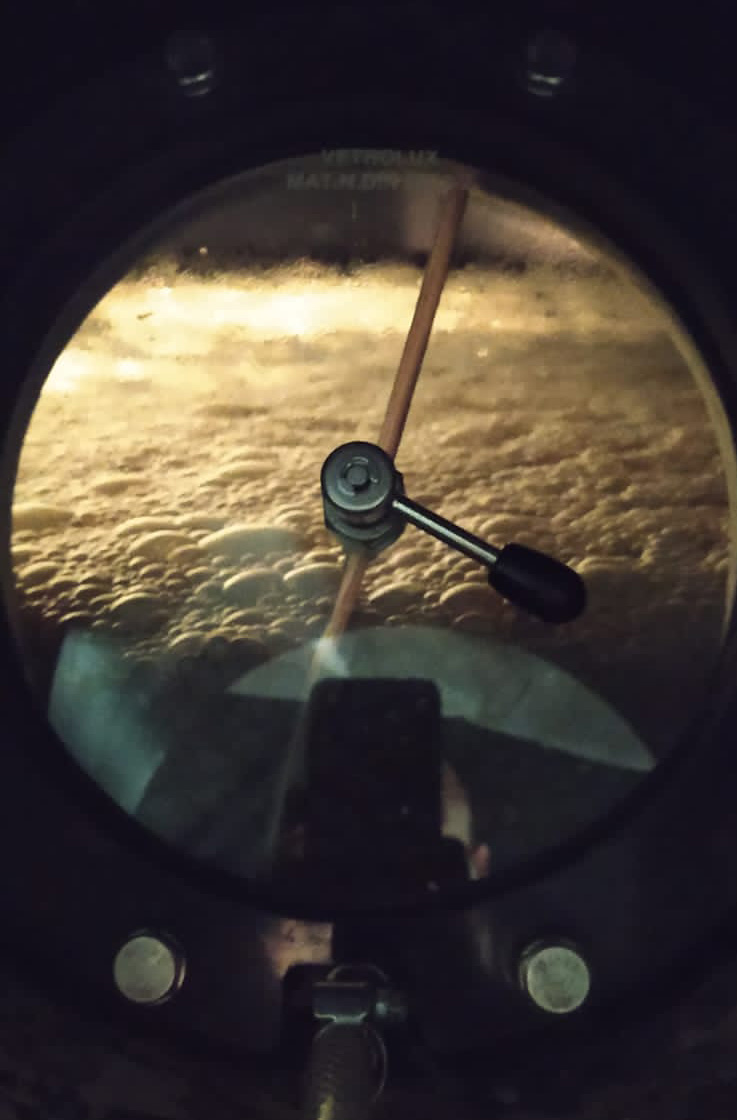

- Health Check of the plant with Infra Red thermograph, thermal camera, methane laser with spectrophotometer, biogas analyzer, automatic FOS/TAC meter and gas chromatograph:

> Detection of gas leaks

> Measurement of methane in CHP exhaust emissions

> Video and photo delivery of any leaks

> On-site measurement of methane, oxygen and hydrogen sulphide

> Alkalinity measurement, FOS/TAC on site - Counsulting through:

> Suggestions for combining raw materials

> Reduction of plant operating costs

> Optimum Desulfurization Proposal

> Increase and Stabilize biogas production

> Biogas quality improvement (methane increase)

> Dealing with specific problems of the anaerobic process

Development of Biomethane Projects

We provide Consulting Services for the choice of technology for Biogas upgrading and Biomethane production, either for fuel (CN

G) or for injection into the Natural Gas Network.

Examples

Biogas 500 kW

- Stabilization of biogas production and increase of methane (from 55% to 60%) by adding suitable trace elements customized blend.

- Dilution of the floating layer by adding in the recipe of the trace elements a specialized product.

Biogas 500 kW

- Transition from mesophilic to thermophilic process (55 C) in two months.

- Increasing biogas production to yield 1000 kW from 500 kW with the same Digester (single stage digestion).

- Stabilization of production using trace elements.

Biogas 1 MW

Detection of leaks in the Digester and piping/connection areas using a thermo-camera.